Key advantages of anodized aluminum:

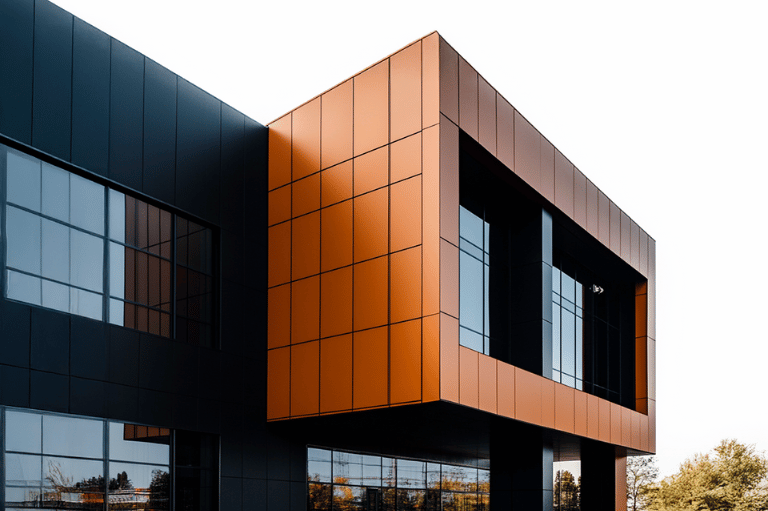

When it comes to premium aluminum finishes, anodized aluminum stands out as the top choice for industries demanding aesthetics, performance, and sustainability. Whether you’re designing architectural marvels, cutting-edge electronics, or durable outdoor products, anodized aluminum offers a blend of style and strength unmatched by traditional alternatives.

Explore the transformative properties of anodized aluminum and discover why it’s the trusted solution for projects where quality, longevity, and environmental responsibility matter most.

Amplified natural finish

Natural Luster High End Finishes: Anodizing offers unique, unmatched finishes, including clear aluminum, copper, and bronze, as well as sophisticated black finishes with excellent UV resistance.

Depth and Richness: The anodized layer thickness can be controlled; longer anodizing times generally result in darker, richer colors. The porous nature of the anodized surface allows for better dye absorption, enhancing color depth and intensity.

Color Matching: Advanced, industry-leading techniques enable us to match colors with remarkable accuracy, ensuring consistency across all your projects.

Perforating and Embossing Compatibility: Anodizing permits secondary processes without compromising finish quality, making it suitable for intricate designs or textures.

25% lower lifetime cost

Initial Cost: Anodizing is often more cost-effective than painting.

Lower Maintenance Cost: Anodized aluminum requires less maintenance over time. It doesn’t chalk, flake, chip, or peel, leading to reduced upkeep expenses. The durable anodized finish requires less frequent cleaning, about half as often as painted surfaces, further contributing to cost savings.

Long-Term Cost Savings: Anodized aluminum eliminates the need for repainting every 5 to 10 years, unlike painted surfaces that deteriorate over time.

50% less maintenance over their lifespan

Scratch and Abrasion Resistance: Anodized aluminum is second only to diamonds in terms of hardness, making it naturally more resistant to scratches and abrasions than paint.

Corrosion Resistance: Anodized aluminum is ideal for outdoor applications due to its inherent rust and corrosion resistance. If the anodic layer is damaged, the aluminum naturally forms a protective oxide layer, preventing further deterioration.

70-Year Warranty: When we say our anodized aluminum finishes are durable, we mean it. Backed by our 70-year warranty, your investment in performance, durability, and aesthetic beauty is guaranteed to outlast the test of time. It’s not just a warranty, it’s a legacy.

Anodizing is an eco-friendly 100% green process

Non-Toxic Process: Anodizing is primarily an electrochemical process that doesn’t involve heavy metals or hazardous chemicals, resulting in no harmful byproducts.

Enhanced Recyclability: Anodized aluminum can be recycled without significant degradation in quality, reducing the demand for virgin aluminum and conserving resources.

No VOC Emissions: Unlike some surface treatments, anodizing does not emit harmful volatile organic compounds (VOCs).

Natural Oxide Layer: The anodizing process creates an oxide layer from the aluminum itself without adding extra materials, ensuring the anodized aluminum remains “recycle-neutral.”

95% + customer satisfaction rating

Lorin Customer Satisfaction: We have a 95%+ customer satisfaction rating driven by color consistency, product durability, and availability.

Customers For Life: 70% of our customer base are customers who buy from us repeatedly.

Versatility and Aesthetic Appeal: Anodized aluminum’s ability to be colored with vibrant, fade-resistant dyes enhances its popularity in consumer electronics and architectural elements, contributing to high customer satisfaction.

Lorin Wrote the Book on Anodizing

Over 80 Years of Expertise: Lorin Industries has been a leader in coil anodizing since 1943, offering customers a range of creative possibilities with the experience of processing over 1.5 Billion lbs of material.

Product Pioneers: We invented the process of continuous coil anodizing, ensuring the consistency of every coil we produce. Our process reflects our unmatched expertise and commitment to quality.

Culture of Innovation: With Lorin, you’re not just working with a supplier, you’re working with an innovative partner. Our team offers engineering support, custom solutions, and technical guidance to make sure your projects succeed.

Unique Unmatched Finishes

ClearMatt®

Dark Bronze Colorin®

Medium Antique Copper

BlackMatt Colorin®

GreenBrite®

BlueBrite®

RedBrite®

Weathered Rust

CopperBrite®

Colorin® BlackMatt (UV)

Champagne Gold (UV)